Are you struggling with an aging boiler system from the 1970s-90s?

Legacy boilers from that era are reaching the end of their operational life, likely burdening your organization with frequent breakdowns and repairs.

Let BES Engineering take care of it. We provide a complete, end-to-end solution—from design and manufacturing to installation and maintenance—all for 50-70% of the typical market price.

For companies and municipalities operating industrial boilers built between the 1970s and 1990s, the challenges are becoming increasingly apparent. Are you struggling with frequent breakdowns caused by age-related deterioration, and the spiraling repair costs that follow each incident? Are you concerned about how long your system can continue to operate safely, and questioning the cost-effectiveness of decommissioning your current boiler and investing in a new one?

Typically, the service life of an industrial boiler is said to be 30 to 40 years. Beyond this period, oxidation and corrosion can reduce the structural integrity of the boiler body, leading to frequent failures of tanks, piping, and control components, as well as a significant decline in operational efficiency. While it is possible to continue operating the system by repairing each fault as it occurs, the mounting repair expenses will severely undermine the overall cost-effectiveness of the system. The most fundamental solution is to decommission the aging boiler and install a new one.

However, a significant challenge lies in the high cost of boilers from major domestic Japanese manufacturers. Furthermore, in recent years, many of these companies have shifted their focus towards large-scale industrial boilers. This has created a situation where there are fewer domestic options available for the replacement of small to medium-sized boilers, which are the most widely used systems.

Sourcing boilers and equipment from overseas may seem like a less expensive alternative, but both large and small companies often face significant quality issues. This can lead to a scenario where costly modifications are required after the equipment arrives in Japan, ultimately inflating the total cost. There have also been cases involving fraudulent reporting or deception by overseas firms, sometimes forcing companies to abandon the project altogether. Another issue is that when Japanese companies intervene excessively in quality control, even for equipment produced overseas by major brands, the final cost can end up being comparable to domestic prices.

Success in international projects also hinges on mutual respect and collaborative partnerships. A top-down or condescending approach during negotiations can be problematic in any country, and this style is known to be particularly ineffective when working with companies in regions such as China.

What we are committed to delivering is an industrial boiler that brings you genuine satisfaction. This means a product that is not only "high-quality" and "low-cost," but above all, one that you can operate with complete "safety and reliability." The confidence behind this promise is forged in our powerful partnership with our partners in China, built on a shared and unwavering commitment to quality.

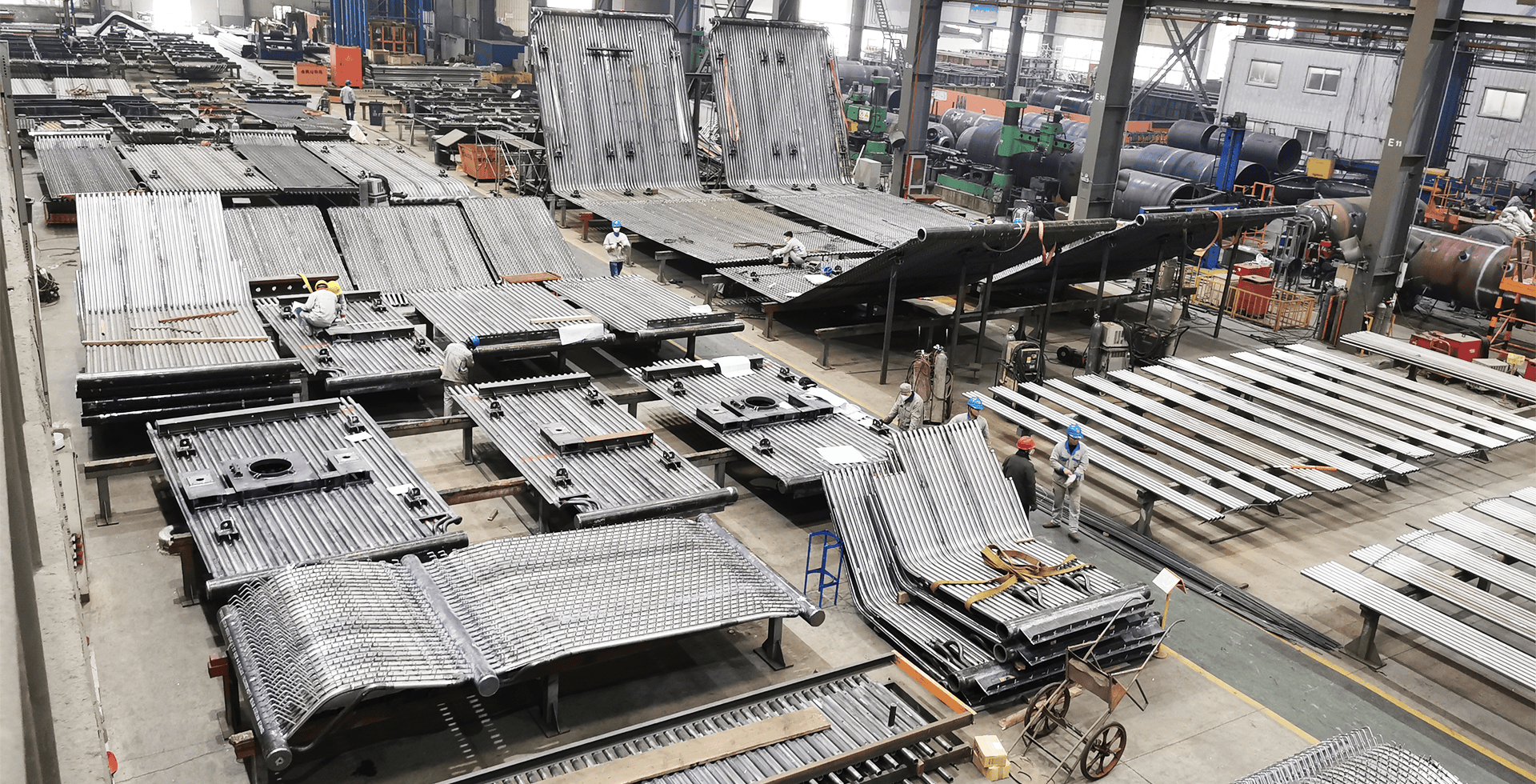

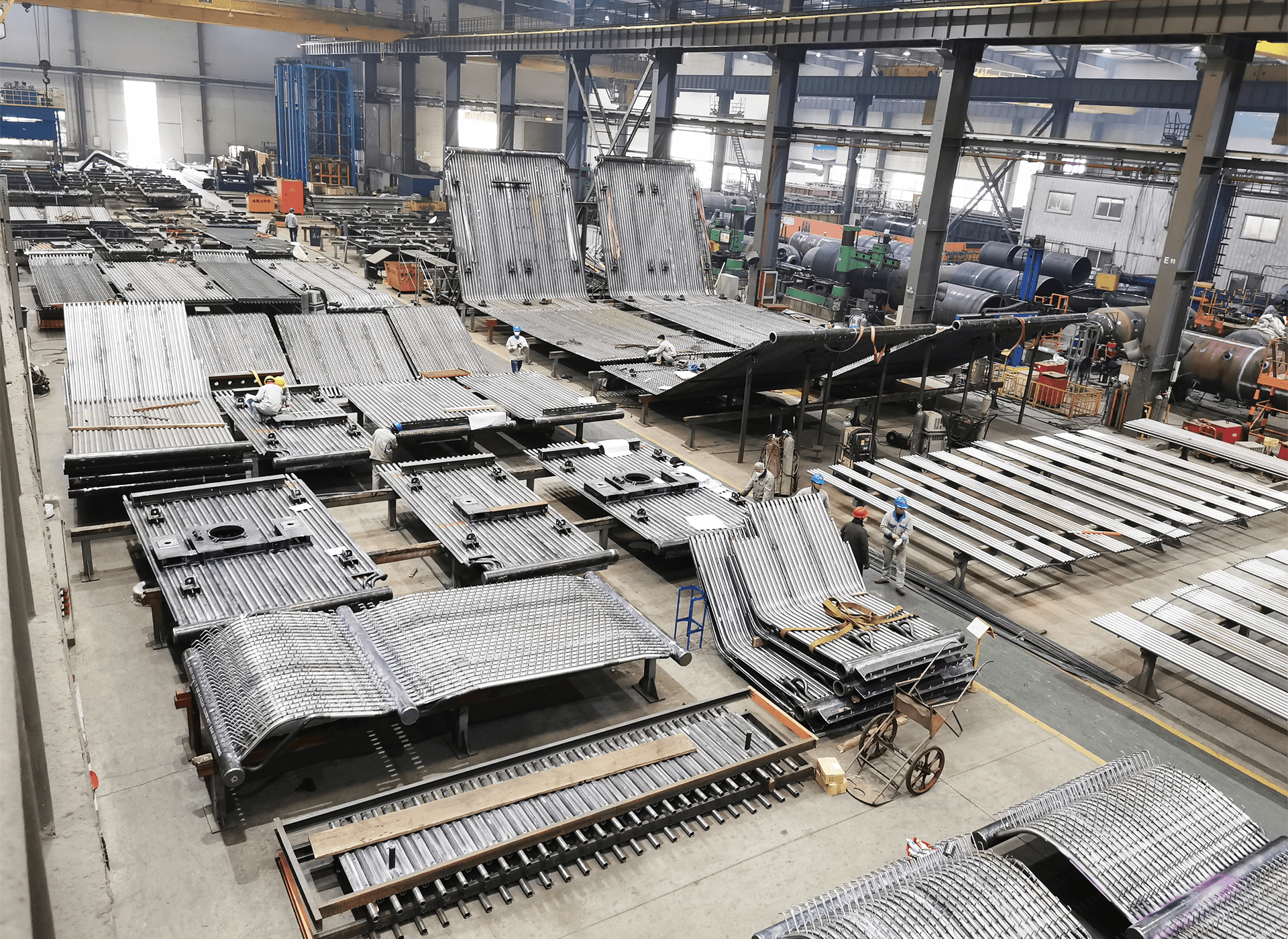

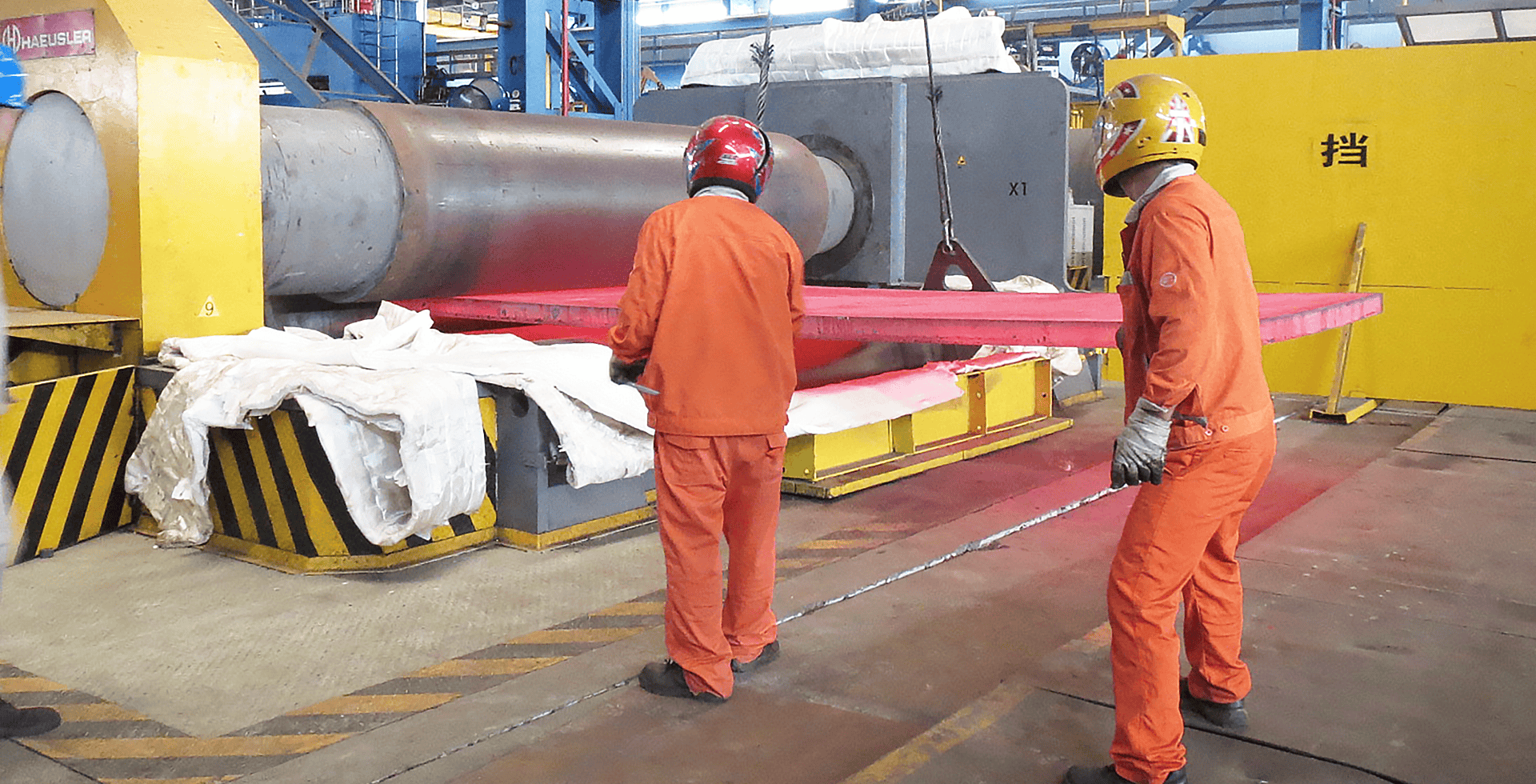

We have chosen to partner with an exceptional Chinese company that shares our passion for quality improvement. Together, we have established a unique quality control framework that is proudly managed by our local Chinese team, empowering them to uphold the highest standards. This fosters a deep sense of pride and responsibility in every product they create.

Symbolic of our quality management is the full-day review meeting we hold after every single project. At these meetings, everyone from on-site workers and foremen to quality control staff, designers, and top management gathers around the same table. The purpose is not to assign blame for mistakes. Rather, it is to seriously consider, as equals, "How can we make this even better?" and "How can we eliminate errors altogether?"

This sincere dedication has produced tangible results. The number of defects, which once numbered in the hundreds, has now been reduced to fewer than ten per project. Furthermore, we recognize and reward employees who contribute to quality improvement with awards and bonuses. By celebrating their efforts, we cultivate a vibrant workplace culture where the drive to "make it better" is always present.

Our products are the crystallization of this rigorous system and the passionate dedication of our people. It is because of this unique combination that we can confidently deliver on our promise of "safety and reliability" to you.

If you would like to know more about any of our products or services, please do not hesitate to contact us.

You can use the inquiry form on this site or contact us by telephone.