"Is our boiler reaching its limit?" If that thought has crossed your mind, feel free to talk to us.

Have you ever found quotes from major plant manufacturers to be far too expensive, or felt like your project wasn't given serious consideration?

We provide high-quality boilers at 50-70% of the cost of major brands, complete with comprehensive maintenance contracts to fully support your system for years to come.

Across Japan's industrial landscape, many boilers are aging and due for replacement. However, many companies hesitate to take the next step, even if they feel their boiler is "reaching its limit." A primary reason is that while boilers from major plant manufacturers offer high quality, they often come with a high price tag, creating a significant investment burden, especially for small and medium-sized enterprises.

Furthermore, it is not uncommon for large manufacturers to be less responsive to smaller-scale projects or to only provide prohibitively expensive quotes. For any boiler, regular post-installation maintenance is the key to stable operation, making a reliable, long-term support system essential. These challenges—high replacement costs, unresponsive service for smaller projects, and ongoing maintenance concerns—have become a significant issue for securing stable heat sources in domestic industries.

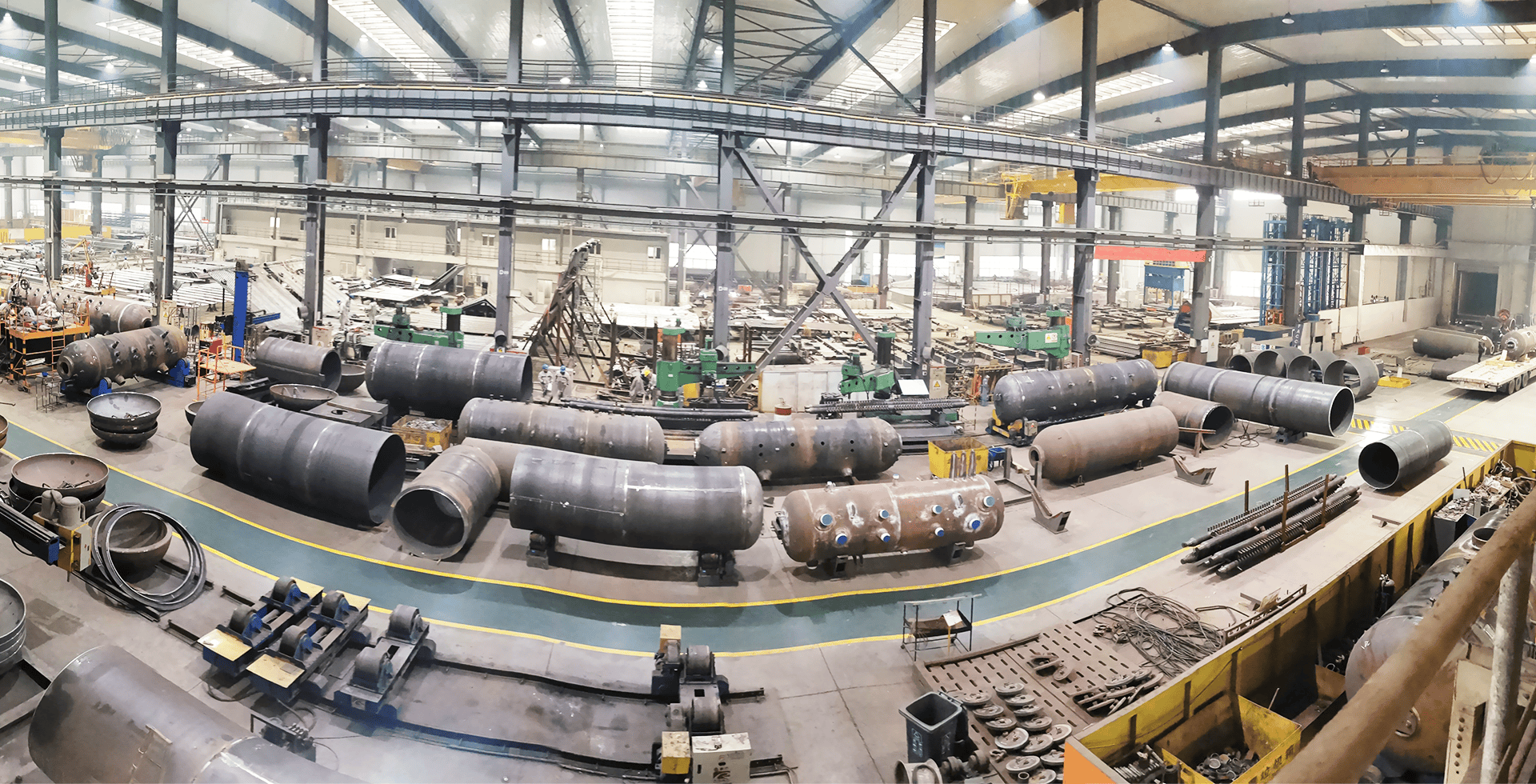

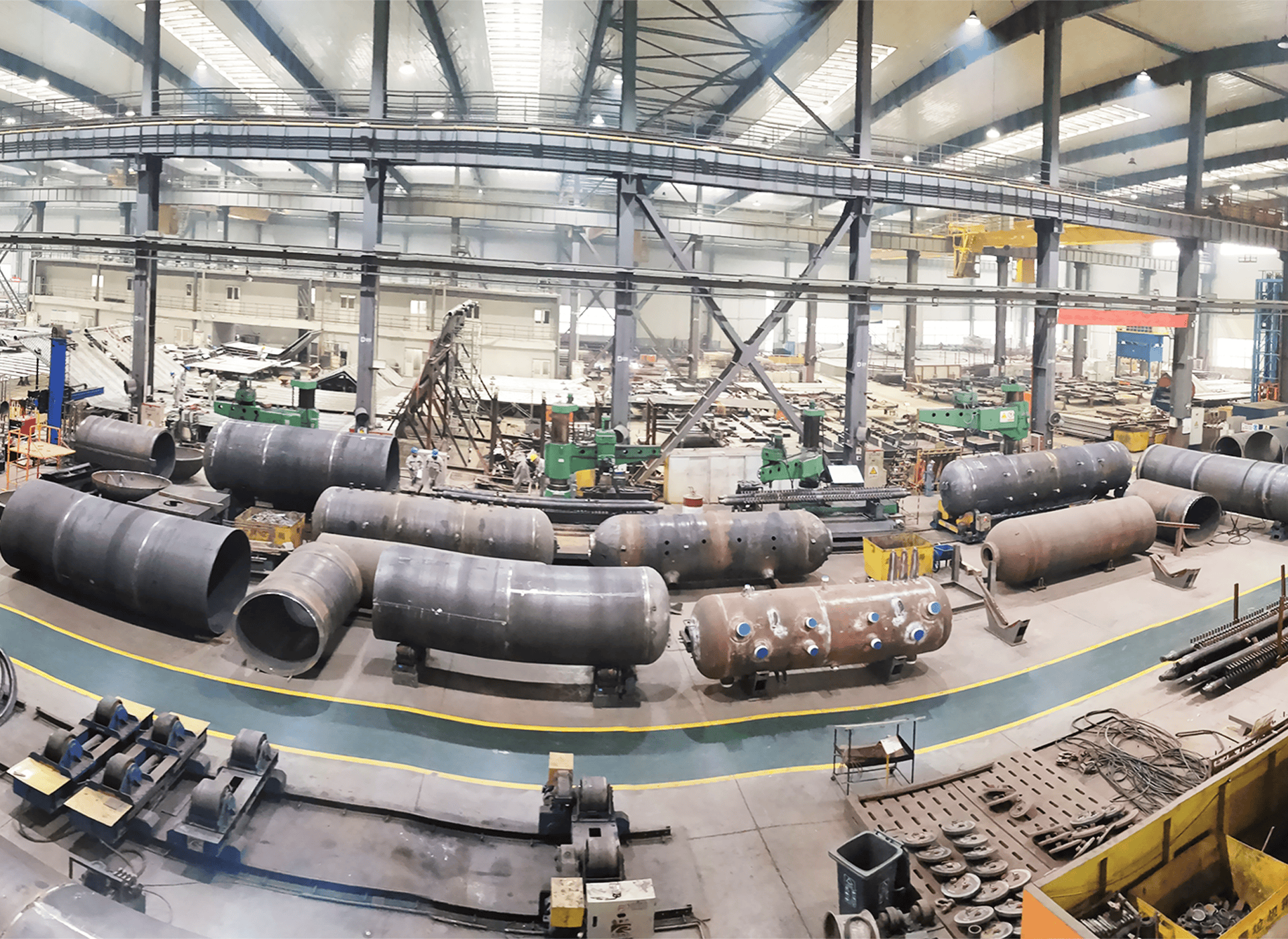

BES Engineering is a specialized vendor dedicated to solving these exact customer challenges. We provide complete, end-to-end support for every process, from boiler design and manufacturing to on-site installation and post-operation maintenance. We are able to offer this total support package for your boiler at just 50-70% of the typical market price.

We invite you to consult with BES Engineering.

Multiple factors can affect the service life of an industrial boiler, but many are external, such as corrosion caused by combustion gas or erosion from entrained ash and dust. On the other hand, internal corrosion and erosion from boiler water and steam are often considered to be caused by improper water quality management.

External factors, in particular, can significantly shorten a boiler's lifespan. Therefore, the analysis of combustion gas is a crucial key to proper maintenance and management of the boiler.

BES Engineering provides highly durable, corrosion-resistant boilers. To achieve this, we offer two primary solutions: one is to increase the thickness of the pipe walls in accordance with the expected corrosion rate, and the other is to weld a corrosion-resistant metal onto the surface of areas prone to corrosion. The first method, increasing wall thickness, adds to the boiler's overall weight and may impact the foundation and steel support structure.

The second method is a technique called Overlay Welding. This is a process where a layer of weld metal is applied seamlessly onto a metal surface, allowing for surface modification tailored to the specific application. Our Chinese partner company has a proven track record with this automated welding technology, having successfully implemented it for Japanese municipalities and clients in Europe.

This technology makes it possible to add a level of wear and corrosion resistance to components like water-cooled walls and superheaters that is difficult to achieve for many Japanese companies. We believe this advanced overlay welding technique is a solution highly worth considering for significantly extending the lifespan of your boiler.

Conventional industrial boilers in Japan, often referred to as "Rōki Boilers," are regulated under the Industrial Safety and Health Act by the Ministry of Health, Labour and Welfare. Their primary purpose is legally defined as the safe generation of steam to supply thermal energy for factory processes and other applications. As a result, their design and operational standards are specialized for steam supply, and they are generally not intended for power generation.

This specific focus creates several disadvantages in terms of energy utilization. First, the application of the thermal energy (steam) generated by the boiler is limited, precluding options such as improving overall energy efficiency through power generation or achieving electricity self-sufficiency.

Second, depending on process conditions, surplus steam may be produced. With these conventional boilers, this surplus energy cannot be used for power generation, potentially leading to significant energy loss. Consequently, users miss out on key benefits such as reducing electricity costs through self-generation and enhancing resilience against power shortages or blackouts.

In summary, the primary drawback of these standard regulated boilers is their inherent inability to be used for power generation, a key means of effective and comprehensive energy utilization.

Your current boiler, regulated for steam generation (under the Ministry of Health, Labour and Welfare), serves the primary purpose of providing steam. However, by converting it into a power generation boiler (regulated by the Ministry of Economy, Trade and Industry), it is possible to unlock significant new value.

In recent years, with the growing risks of power shortages and planned outages due to climate change, securing a stable in-house power supply has become a critical business challenge. By repurposing your existing boiler into a power generation facility and operating it in a highly fuel-efficient state, you can continue to use steam for your processes as before, while also generating electricity from surplus steam.

This conversion allows you to utilize the generated electricity for your own on-site power needs, leading to reduced electricity costs and a more stable energy supply. While this requires an initial investment, generating your own power from boiler steam is an effective strategy to prepare for the risks of an unstable power grid and to achieve more sustainable energy utilization.

BES Engineering provides thorough support for this entire process, including navigating the complex application procedures with the relevant government ministries and managing all necessary equipment modifications and expansions.

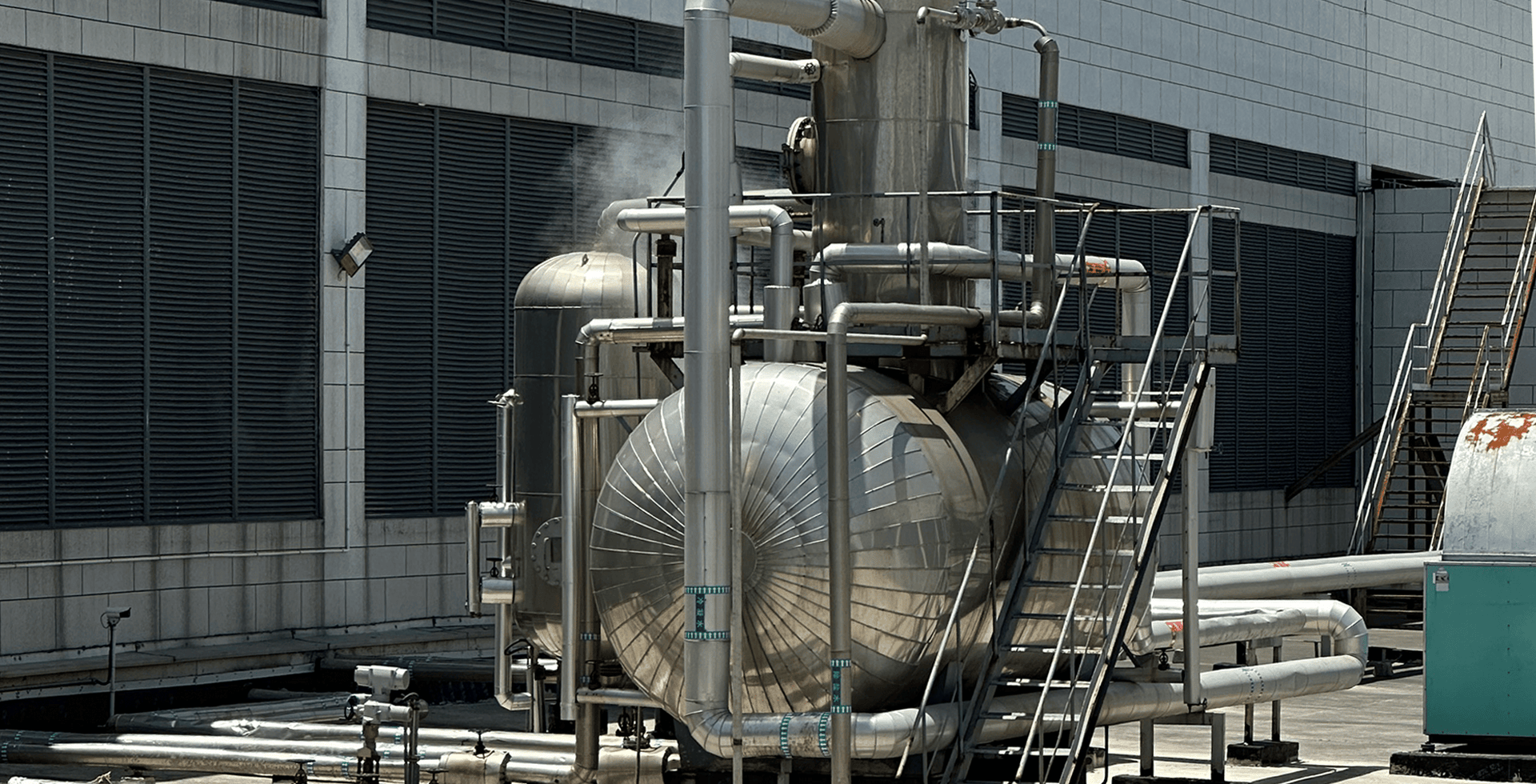

When you hear the term "energy recovery," you might think it requires special equipment or a complex undertaking. However, we invite you to look at your factory from a new perspective. Beyond common energy-saving measures like reducing lighting, there is another approach: recovering heat that has been previously overlooked.

The reality is that in many factories, a significant amount of valuable, reusable thermal energy is contained in the steam, hot water, and exhaust gases discharged from boilers and other equipment. In many cases, this energy is not being fully utilized and is simply discarded or released into the atmosphere. Furthermore, in facilities with aging boiler systems, it is likely that even more heat is being wasted.

Recovering and effectively utilizing this "hidden energy" is a critical initiative. It not only leads to a reduction in your environmental footprint but also contributes directly to lowering the overall energy costs for your entire factory.

f you are concerned about factory waste disposal and soaring energy costs, BES Engineering's Waste-to-Energy Boiler Solution can help as a groundbreaking system that solves both challenges at once.

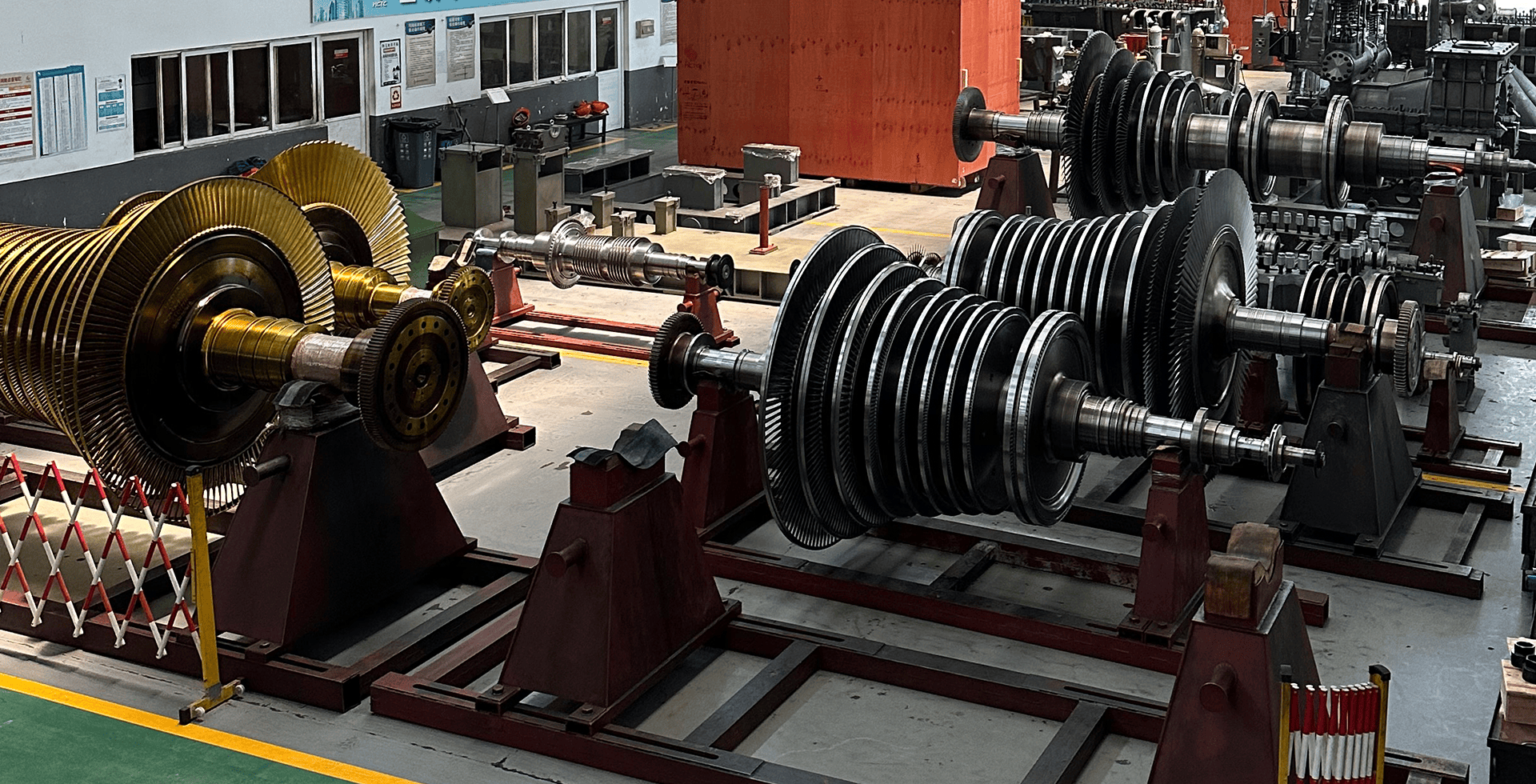

Our solution works by harnessing the thermal energy generated when incinerating waste from your own factory. Instead of letting this heat go to waste, we use it in a boiler to produce steam, which in turn drives a turbine generator to create electricity. In essence, what was once treated as disposable waste is regenerated into valuable electrical energy.

The implementation of this system enables you to secure your own in-house power supply year-round. This not only contributes significantly to reducing your electricity bills, particularly demand charges, but also improves your business continuity. You can create an environment where you can focus on your core production activities without being affected by risks like power supply instability or planned outages, even during peak summer and winter seasons.

We at BES Engineering are dedicated to helping you maximize the unutilized energy within your factory to achieve both cost reduction and stable operations. We invite you to take this opportunity to consider our Waste-to-Energy Boiler Solution.

If you would like to know more about any of our products or services, please do not hesitate to contact us.

You can use the inquiry form on this site or contact us by telephone.